Sinco-Jet

Fabric Cleaning & Conditioning

Fabric Cleaning & Conditioning

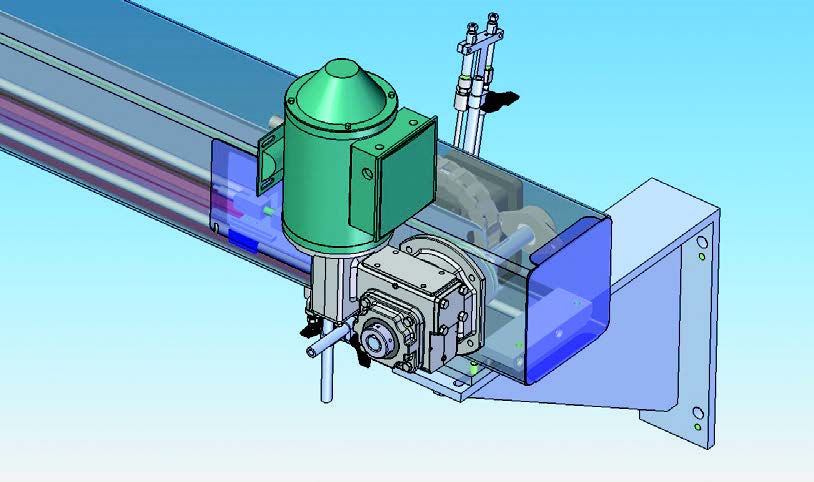

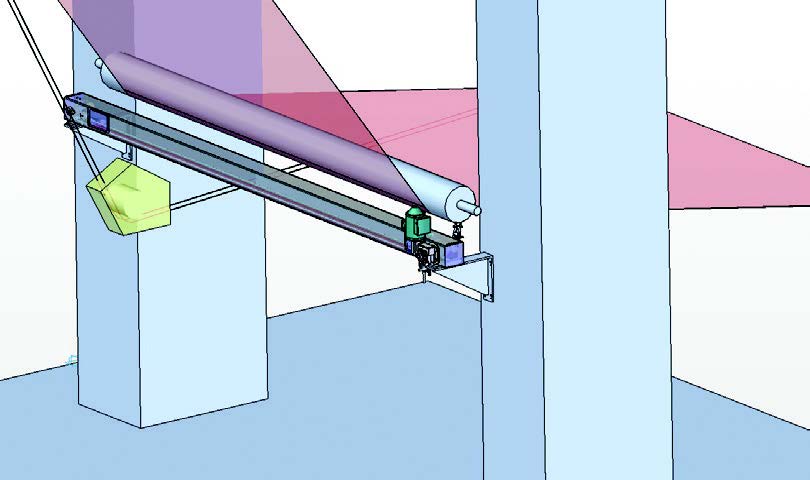

The Sinco-Jet is designed to optimize performance of the paper machine clothing. A single or small cluster of nozzles jettison high pressure water, by jet or fan nozzle, to remove embedded particles to clean and condition the fabric. This single or small cluster of nozzles is efficient in cleaning the fabric while using a relatively small volume of water when compared to conventional multiple nozzle showers. The smaller volume of water means quicker fabric drying time, thereby reducing fabric drying costs.

OPERATION

A standard cleaning nozzle traverses the fabric until the entire fabric is cleaned. The nozzle then either continues its cleaning cycle on the nozzle return stroke or "rapid reverses," returning the nozzle to the original starting position and continues the next cleaning cycle. The Sinco-Jet control consists of a PLC controller and an operator interface touch pad. The touch pad allows the operator to choose the desired cleaning mode and to set appropriate operating parameters. There are a total of four modes of operation to choose from of which three are running modes along with a maintenance mode.

A standard cleaning nozzle traverses the fabric until the entire fabric is cleaned. The nozzle then either continues its cleaning cycle on the nozzle return stroke or "rapid reverses," returning the nozzle to the original starting position and continues the next cleaning cycle. The Sinco-Jet control consists of a PLC controller and an operator interface touch pad. The touch pad allows the operator to choose the desired cleaning mode and to set appropriate operating parameters. There are a total of four modes of operation to choose from of which three are running modes along with a maintenance mode.

THE SINCO-JET ADVANTAGE

Increased use of recycled fiber makes it very difficult to keep fabrics open and clean. Frequently, dryer fabrics are removed because they become plugged and are no longer efficient. Embedded particles can also act as an abrasive causing the fabric to wear out prematurely. By using the Sinco-Jet, fabrics remain more open allowing the paper machine to operate at a higher speed and with more efficiency.

AVAILABLE OPTIONS

Depending on the specific fabric application, a variety of nozzles may be installed. For most applications a standard 15º fan nozzle with an approximate 1/2" to 1" cleaning path is used. For fabric requiring the maximum cleaning condition, a needle-jet nozzle can be installed. Due to a much narrower cleaning path a longer cleaning time is required. Other nozzle configurations are available. Also a second trailing air blowoff nozzle can be added to help remove water from wetted wire or fabric.

Depending on the specific fabric application, a variety of nozzles may be installed. For most applications a standard 15º fan nozzle with an approximate 1/2" to 1" cleaning path is used. For fabric requiring the maximum cleaning condition, a needle-jet nozzle can be installed. Due to a much narrower cleaning path a longer cleaning time is required. Other nozzle configurations are available. Also a second trailing air blowoff nozzle can be added to help remove water from wetted wire or fabric.

FEATURES

Variable Mode Control

Manual Mode

Semi-automatic continuous cleaning mode. The desired cleaning parameters are entered. The operator must manually calculate and enter the optimum nozzle traversing speed, based on fabric running speed.

Auto Mode

Automatic cleaning mode. The operator enters desired cleaning parameters. Nozzle traverse speed is synchronized with feedback input from the paper machine fabric speed controller.

Spot Clean Mode

This concentrates the cleaning to an identified section of fabric that may occasionally need more assertive cleaning. Operator enters specific pattern parameters. Upon a completed cycle the system is returned to the previous manual or auto cleaning mode.

Maintenance Mode

This mode shuts down the cleaning modes and returns the nozzle to a nozzle maintenance access position.